CAR tech

Did you know that a good task planner in the workshop can improve business operational efficiency by up to 25%?

CAR team · 22/08/2025

In a repair shop, every minute counts. Good organization not only affects how quickly vehicles are serviced, but also the perceived quality of service by the customer and the satisfaction of the technicians on the team (we all like our work to shine). A workshop with solid task planning and assignment is more efficient, has happier customers, and fosters a better work environment among employees. That’s why task planning and assignment become a key element in achieving efficient business operations.

Let’s explore the fundamental aspects of planning and optimally assigning tasks among workshop technicians, the benefits of using electronic planners, and most importantly, the results being achieved by workshops already using this type of technology.

Essential Points of Task Planning

- Workload analysis: Understand which repairs are scheduled each day, their complexity, and estimated execution times.

- Assignment based on skills: Distribute tasks according to each technician’s specialization (mechanics, electrical, bodywork and painting, electronic diagnostics, etc.).

- Repair prioritization: Set execution order based on customer urgency, parts availability, and delivery commitments.

- Material resource management: Ensure each task has the necessary parts, tools, and equipment, avoiding delays due to unforeseen issues.

- Monitoring and feedback: Track repair progress and gather information to adjust future planning.

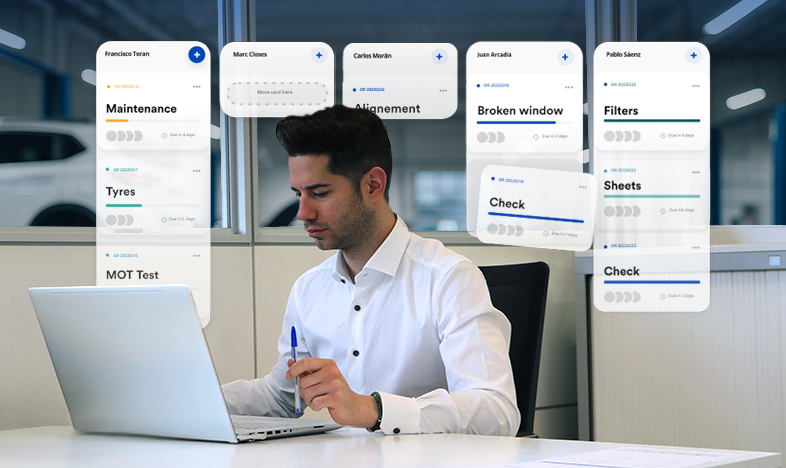

The Value of an Electronic Planner

Today, many workshops still manage tasks manually (notes, spreadsheets). However, an electronic planner offers decisive advantages:

- Real-time visibility: All technicians and managers can check the status of ongoing repairs.

- Time optimization: Reduces idle time by automatically assigning tasks to available technicians.

- Reduction of human errors: Prevents oversights and scheduling overlaps.

- Flexibility: Allows quick task rescheduling in case of unexpected events, such as urgent part arrivals or priority breakdowns.

- History and metrics: Generates reports on productivity, repair times, and individual and team performance.

Improvement Indicators with Digital Planning

Workshops that implement an electronic planning system often show notable improvements within a few months. According to various studies and industry experiences:

- Operational efficiency increases by 15% to 25% thanks to reduced wait times and better resource allocation.

- Delivery delays decrease by 20% to 30%, strengthening customer trust.

- Staff satisfaction rises by around 18%, as they receive clear tasks aligned with their skills.

- Administrative errors drop by up to 40%, due to automated tracking and records.

- Customer satisfaction improves, with loyalty rates increasing by up to 25% thanks to punctuality and service transparency.

In Summary…

A vehicle repair workshop should not only invest in cutting-edge tools and equipment, but also in strategic task planning. Implementing an electronic planner like Car Planner transforms daily management into a much more efficient process, boosts technician productivity, and ultimately ensures higher quality service for the customer.